Full service turn-key capable CNC machining and sheet metal fabrication manufacturer

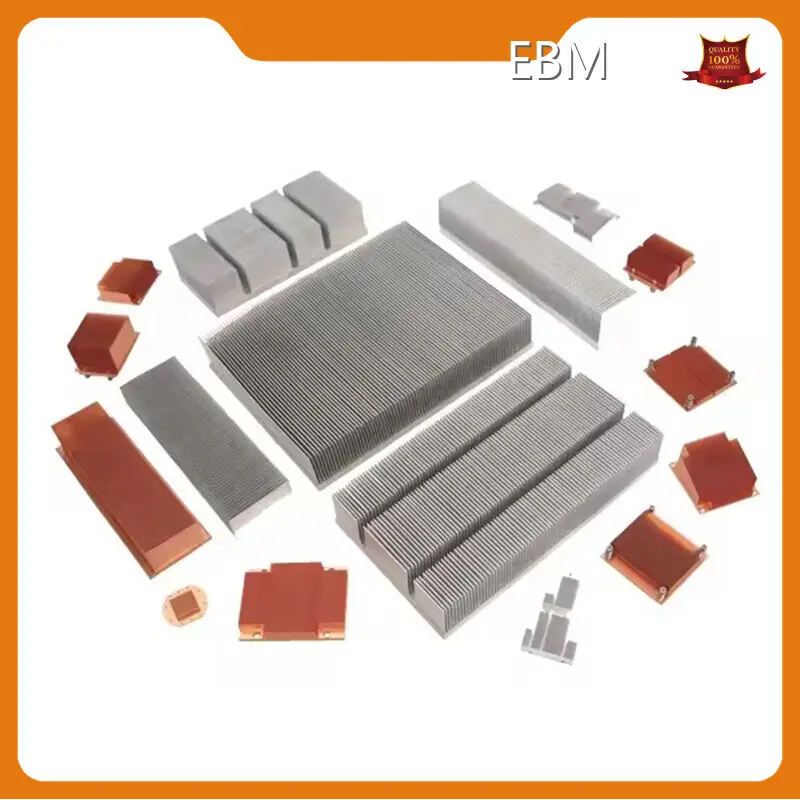

Machining Parts Manufacturers Supplier EBM

Product details of the machining parts manufacturers

Quick Detail

Being expertly conceived, EBM machining parts manufacturers shows an award-winning design. The product is of highest quality and manufactured under strict quality control system. Our service for machining parts manufacturers covers from design, production to installation and technical support.

Product Information

Compared with similar products, EBM's machining parts manufacturers has the following advantages.

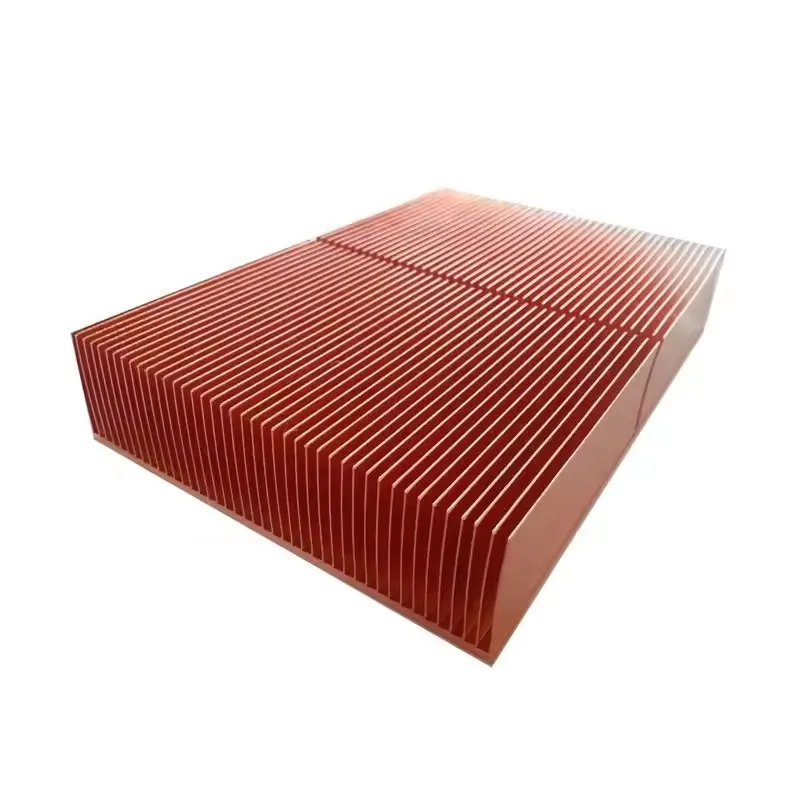

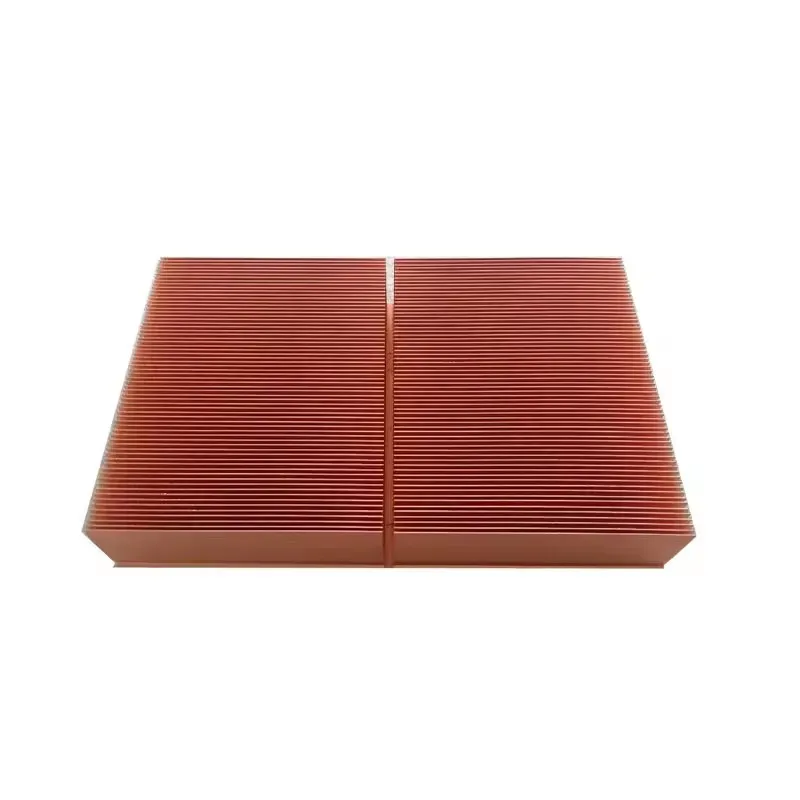

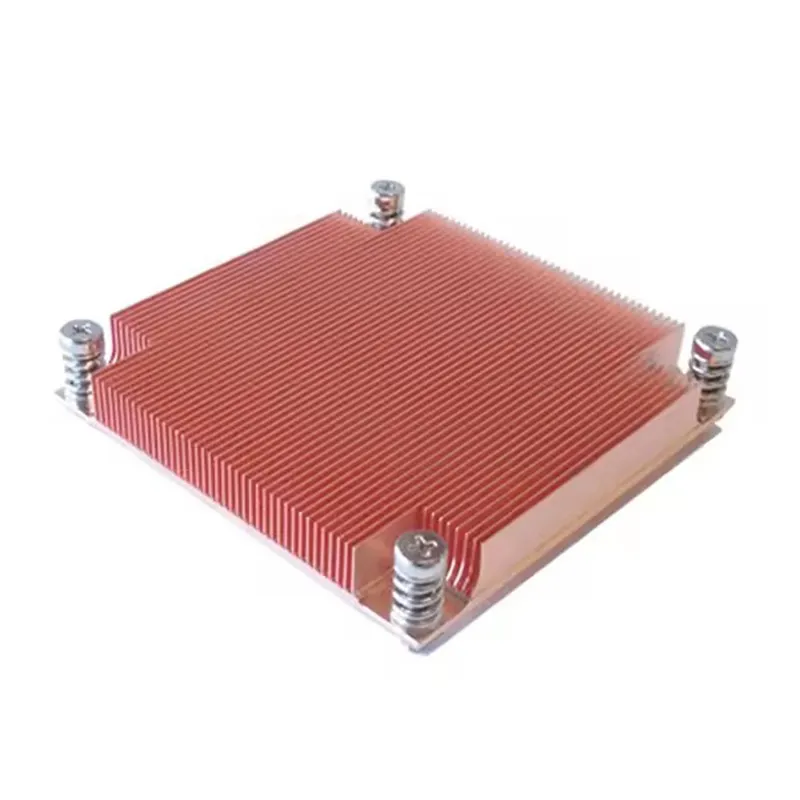

| Item Name | Skiving heat sink, CNC machined heat sink, Extruded heat sink |

| Material | Aluminum: AL 6061, 6063, 6082, 7075, etc |

| Copper: C1100, C1020 | |

| Stainless Steel: 303, 304, 316, etc | |

| Brass: 3602, 2604, h59, h62, etc | |

| Plastic: POM, PC, Acrylic, Nylon, etc | |

| Machining Equipment | 3-5 axis cnc milling machines, CNC lathes, EDM machines, Grinding machines, laser cutting machine, bending machine, welding machine. |

| Finish | Sand blasting, Color anodize, Brushing, Polishing, Plating, Painting |

| Inspection equipment | CMM, Tool microscope, multi-joint arm, Dial gauge, Marble platform, Roughness measurement, Digital height gauge, caliper, Projection machine, Hardness tester and so on. |

| Drawing Formats | Solid Works,Pro/Engineer, AutoCAD(DXF,DWG), PDF,TIF etc. |

| Packaging | 1.Standard strong carton package + Pallet/ Wooden case |

| 2. Per customer's requirements | |

| Delivery | Sample: 5-10 days |

| Mass Production: 15-30 days depends on quantities | |

| Process capability | We can work with your design team or handle the design work for you, build prototypes, and perform design validation and testing. Then design and implement value-line manufacturing processes including any and all finish types neeeded. We can assemble your product and manufacturing your packaging including full print services. |

| Application | Aerospace, Aviation, Agriculture, Marine, Electronic, Automobile, Communication, Drone, Medical, Solar energy, Home Appliance, etc |

CASTING SERVICES

Casting molten metal is one of the oldest manufacturing processes--goig back at least 5,000 years to craftsmen in Mesopotamia who created omaments using copper. The Bronze Age propelled cicilization forward with cast tools and of course weapons. The use of reusable stone molds appeared around this time greatly speeding up the process. In 1300 BC, the Shang Dynasty in China developed.

Sand casting. About 800 years later,the Zhou Dynastu figured out Iron casting which was used primarily for farm tools. Jump to 1313 Ghent(now Belgium) adn a Monk using the dregs from beer rewing bats as a sand binder for casting bells,cast the first cannon.

Casting is a great way to lower manufacturing costs for metal parts that need to be made at higher volume. Because it is an additive process rather than a subtractive process--like CNC machining material costs tent to be lower. EBM can help you optimize your design for casting and select the best casting process for your part. We can also handle any post casting processes you may need everything from surface finishing and CNC machining to packaging and shipping.

CNC SERVICES

Machine shops have been the beating heart of factories since the industrial revolution began in 1750's England. The rapid switch to NC,(Numerically Controlled) machining developed bt MIT in the 1940's and CNC(Computer Numeric Control) in the 1980's that led to the CAD/CAM revloution in the 00's has increased the value and importance of CNC machining in manufacturing.

EBM has full 3 and 5 axis CNC and CAD/CAM machining capabilities and can machine virtually any type of metal and a large host of common and specialized engineering plastics- from small batch prototyping to 50.000 part production runs. Our highly trained and experienced machinists live and breathe machining so if you have a difficult part that other shops have passed on,chances are good that we are up to the challenge.

other service

As a ful service turn-key capable manufacturer with product design and sales offices in the U.S. and an ex-tensive array of highly capable manufacturing facilities in China, EBM is the perfect partner for any comapnylooking to save time and cut costs at every stage of the production process.

We can work with your design team or handle the design work for you, build prototypes, and perform designvalidation and testing. Then desian and implement value-ine manufacturing processes including any and alfinish types needed. We can assemble your product-including designing and building any precision assembly fixtures or igs if needed. We can design and manufacture your packaging including full print servicesNeed UPC/EAN barcodes? We can take care of those for you as well.

Our shipping services include order fulfilment requirments for larger retailers like Amazon and Walmart or tcany specification you reguire--master cartons and crates to palletized to shipping containers. We turn youlideas into finished products.

Company Advantages

东莞市东桥电子有限公司 is a reliable supplier of machining parts manufacturers. After years of development, we are proficient in product design and manufacturing. 东莞市东桥电子有限公司 has advanced production equipment, excellent manufacturing technology and complete testing methods. We put emphasis on sustainability practices in our machining parts manufacturers business. For example, we introduce advanced technologies to deal with production waste to comply with environmental and emission norms.

We have high production efficiency, and we look forward to the cooperation with you.