Full service turn-key capable CNC machining and sheet metal fabrication manufacturer

Aluminium Extrusion Parts: Design Considerations And Manufacturing Process

Welcome to our comprehensive guide on Aluminium Extrusion Parts: Design Considerations and Manufacturing Process. If you're interested in delving deeper into the intricate world of extrusion, this article serves as your go-to resource. Acquainting yourself with the vital aspects of design considerations and the manufacturing process will not only enhance your understanding but also equip you with the necessary knowledge to make informed decisions. So, join us as we uncover the secrets behind creating top-quality aluminium extrusion parts, offering valuable insights that will undoubtedly captivate engineers, designers, and enthusiasts alike.

Understanding the Importance of Design in Aluminium Extrusion Parts

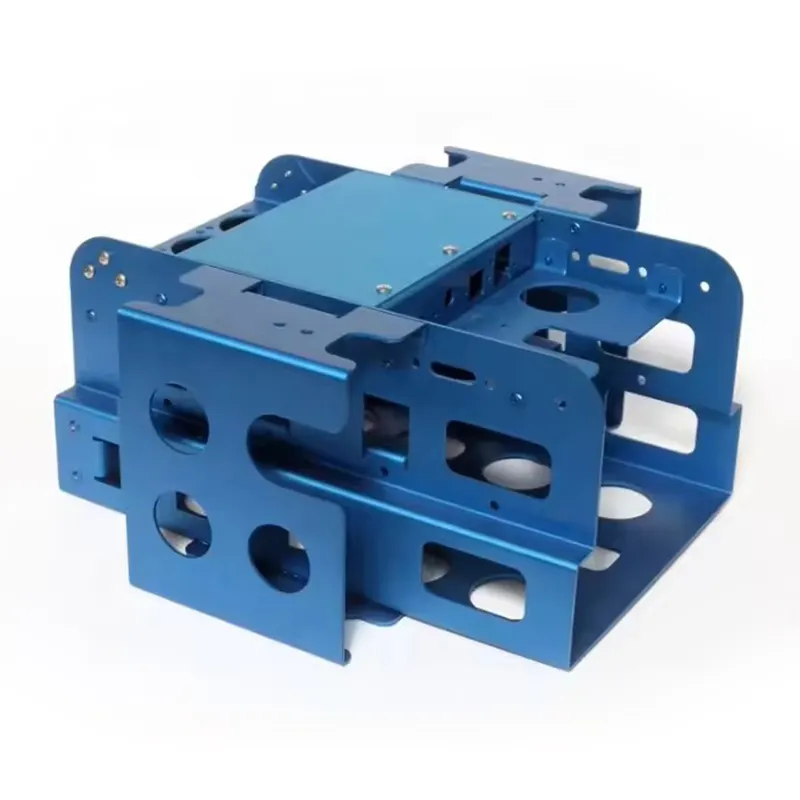

Aluminium extrusion parts play a significant role in various industries due to their versatility, strength, and lightweight nature. When designing these parts, it is essential to consider multiple factors to ensure optimal functionality and manufacturability. In this article, we will explore the design considerations involved in aluminium extrusion parts and outline the manufacturing process employed by our brand, EBM.

Designing aluminium extrusion parts requires careful analysis of the intended application, considering factors such as load-bearing capacity, geometrical complexity, and thermal management. By understanding these considerations, our team at EBM can assist clients in creating superior designs that meet their specific requirements, ensuring durability and efficiency.

Tailoring Aluminium Extrusion Parts to Meet Unique Design Specifications

One of the key advantages of aluminium extrusion is its ability to be customized according to unique design specifications. EBM specializes in working closely with clients to create tailor-made solutions that fulfill their requirements accurately.

Our design team at EBM takes into account the precise dimensions, shapes, and finishes desired by clients. By utilizing advanced computer-aided design (CAD) software, we can simulate the end-product, allowing clients to visualize it before the manufacturing process begins. This comprehensive design process ensures a seamless transition from idea to tangible product, resulting in high-quality aluminium extrusion parts.

The Manufacturing Process: From Billet to Extruded Aluminium Parts

Once the design is finalized, the manufacturing process begins. EBM employs state-of-the-art machinery and techniques to ensure precision and consistent quality throughout the production stage.

The first step of the manufacturing process involves acquiring aluminium billets, which are heated to a temperature suitable for extrusion. The heated billet is then forced through a die under high pressure, resulting in the desired shape. Advanced cooling methods are employed to temper the extruded part and enhance its strength.

Post-extrusion processes, such as cutting, drilling, and finishing, are crucial to achieve the final product's desired specifications. EBM pays attention to every detail during these stages, employing high-tech equipment and expert craftsmanship to ensure accuracy and meet exact client requirements.

Quality Assurance and Testing: Guaranteeing Excellence in Aluminium Extrusion Parts

At EBM, quality assurance is of utmost importance. We subject each aluminium extrusion part to strict testing procedures to ensure its integrity and adherence to design specifications. These tests evaluate factors such as dimensional accuracy, mechanical strength, and surface finish, guaranteeing that the final product surpasses industry standards.

We also offer assistance in material selection, as different alloys possess varying characteristics suitable for specific applications. By considering factors like corrosion resistance, formability, and cost-effectiveness, our experts guide clients in choosing the optimal alloy for their aluminium extrusion parts.

The Advantages of EBM Aluminium Extrusion Parts

EBM takes pride in providing top-quality aluminium extrusion parts that meet and exceed customer expectations. Our commitment to utilizing advanced design and manufacturing processes results in products characterized by exceptional strength, durability, and precision.

Whether you require aluminium extrusion parts for the automotive, aerospace, or construction industry, partnering with EBM ensures reliable and innovative solutions. Trust our expertise to deliver tailored designs, superior manufacturing, and the highest standards of quality in aluminium extrusion parts.

In conclusion, aluminium extrusion parts require meticulous design considerations and a well-executed manufacturing process to ensure their functionality and durability. EBM's expert team and cutting-edge technology enable us to deliver high-quality products that meet even the most demanding specifications, providing our clients with reliable solutions for their diverse needs.

Conclusion

In conclusion, as a company with a decade of experience in the industry, we have learned the importance of considering design considerations and the manufacturing process when it comes to aluminium extrusion parts. Throughout this article, we have explored the various aspects that need to be taken into account, from material selection and die design to post-extrusion treatments. By carefully considering these factors, manufacturers can maximize the quality and efficiency of their extruded parts, leading to improved product performance and customer satisfaction. As we continue to grow and evolve in this industry, we remain committed to staying at the forefront of technological advancements and industry trends, ensuring that we continue to provide our customers with the highest quality aluminium extrusion parts for years to come.